INTE ISM Supply Management Integration Free Practice Exam Questions (2026 Updated)

Prepare effectively for your ISM INTE Supply Management Integration certification with our extensive collection of free, high-quality practice questions. Each question is designed to mirror the actual exam format and objectives, complete with comprehensive answers and detailed explanations. Our materials are regularly updated for 2026, ensuring you have the most current resources to build confidence and succeed on your first attempt.

A wine bar which also serves tapas and sandwiches notices that its customer volume fluctuates significantly (depending on convention tourism and hotel night stays) and that wait times for seating are growing longer. As a result, managing demand for perishable food products is becoming more challenging.

Which of the following would be MOST useful in this scenario?

A company that has never focused on supply management in the past is now faced with increasing competition from new, innovative products entering its market. As a result, the firm's business strategy includes an increased focus on cost containment. Given this situation, which of the following should the company do FIRST?

XYZ Company engages a freight bureau to conduct an audit of its freight forwarder. How can XYZ BEST utilize the information obtained from this review?

When executing a new project, which of the following is MOST important to a smooth transition?

A large retailer and one of its suppliers establish a process to combine intelligence from both organizations in order to improve product availability while reducing inventory, transportation, and logistics costs. This process is known as which of the following?

Over the past 90 days, a buying company's manufacturing engineers have reported an increase in the number of defective parts received from a key supplier. The engineers report that there are three different types of defects occurring, and that they are all being discovered during production. The supplier states that it does not have enough resources to assess the root cause of the three types of defects all at one time. Which of the following should the buying firm do in this instance?

UVX, Inc. is seeking suppliers of components to be used in a new heavy equipment product UVX is introducing in the marketplace. The firm conducts a market intelligence analysis and spend analysis to determine feasibility. These findings are reported to the company stakeholders, who decide to produce 25 units every two weeks. UVX issues a solicitation for bids and includes the stakeholders' requirements with the specifications.

At the close of the bidding process, UVX receives one offer that can deliver enough components to produce 15 units every four weeks. The remaining potential bidders decline altogether, citing an inability to meet UVX’s specifications.

Which of the following should UVX have done in order to ensure a better response to the solicitation?

If a shipment has a gross weight of 500 pounds and overall dimensions of 42 inches x 48 inches x 48 inches, what is the density of the shipment (in pounds per cubic foot)?

During an inventory review, a supply manager confirms that parts used for the maintenance of equipment sold during the previous year are still being stored in the warehouse. These parts cannot be used on current equipment. Which of the following BEST describes these parts’

A manufacturing firm redesigns its premier product to benefit from material standardization. The change will entail re-tooling costs. The firm conducts a cost benefit analysis on four possible options. Option 1 is to make no change at all. Options 2, 3, and 4 represent different re-tooling configurations involving different materials:

Option 1Option 2Option 3Option 4

Re-tooling Costs (Year 1)$0$800,000$1,000,000$1,200,000

Material Costs

Year 151,000,000$700,000$650,000$600,000

Year 2$1,100,000$750,000$700,000$650,000

Year 3SI,200,000$800,000$750,000$700,000

Year 451,300,000$850,000$800,000$750,000

Year 551,400,000$900,000$850,000$800,000

Total$6,000,000$4,000,000$3,750,000$3,500,000

Labor Costs

Year 1$1,000,000$700,000$650,000$600,000

Year 2$1,100,000$770,000$715,000S660,000

Year 3$1,210,000$847,000$786,500$726,000

Year 4$1,331,000$931,700$865,150$798,600

Year 5$1,464,100$1,024,870$951,665$878,460

Total$6,105,100$4,273,570$3,968,315$3,663,060

In addition to this, there will be a cost of $3.5 million in lost production during Year 1, should any of the re-tooling options (2, 3, or 4) be selected.

The firm wants to rank the options in order of financial preference, from the best option to the worst. Based on this information, how should the four options be ranked?

A manufacturer is working to standardize high-volume, low-cost hardware components used in its assembly process. The manufacturer wants to transfer some of the risks associated with inventory carrying costs, warehousing costs, and re-stocking costs to the supplier. Which of the following will be MOST useful in accomplishing this goal?

Which of the following requires investment recovery action’

A firm wants to contract with two suppliers to develop a cellphone tower servicing five million customers. The new technology is required within the next 36 months and has a large budget. The following suppliers are under consideration:

•Supplier A - Has been in business for 20 years; however, every two to three years, its labor force goes on strike

•Supplier B - An established business located in an overseas country which may charge an additional 2% duty on some imported goods

•Supplier C - An established business which has been closed on recent occasions by governing authorities due to health and safety violations

•Supplier D - Has the smallest facilities and workforce of the four, but will be expanding over the next three months and has successfully subcontracted work in order to meet timelines

Based on this information, which two suppliers offer the BEST capacity and capability?

Which of the following is the BEST reason to use Monte Carlo simu-lations to improve a forecast7

A chemical supply company creates a new liquid chemical product which must be shipped by tanker truck. The new chemical is expected to constitute 10% of the firm’s sales over the next five years. The company's other sales are all solid powder chemicals. Given these circumstances, which of the following will be the MOST cost effective method for the company to ship the new product’

A manufacturer receives notice from one of its largest customers stating that, from this point on, it will only accept environmentally friendly boxes for packaging. The manufacturer checks the remaining packaging in its inventory and finds that it still has over six months' worth of boxes that are not made of environmentally-friendly materials. These boxes are custom-designed and cannot be returned to the packaging material supplier. In this situation, the manufacturer would be BEST served by doing which of the following?

An organization purchases material from several countries. These materials are assembled into products and sold in several other countries. This firm's product specifications will MOST likely reference

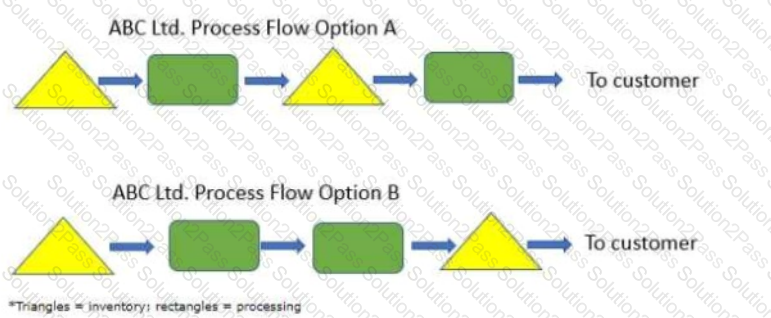

A firm has created the following process flow diagrams depicting two possible strategies for the production of a new product line. The triangles represent inventory, and the rectangles represent processing. Each of the two options start with the same raw materials, and both create the product through two stages of processing.

Which of the following statements is correct?

Which of the following are the quickest ways to ship food products in order to ensure they do not spoil?

A specialized sewing shop quilts fabrics for use in upholstered furniture. Various patterns are produced on different machines, each of which has its own set-up routine. At times, one type of machine is idle while others are backed up. The sewing floor supervisor finds new software which makes the machines' patterns interchangeable. Which of the following is the MOST likely result of upgrading to the new software?