L6M9 CIPS Supply Network Design Free Practice Exam Questions (2026 Updated)

Prepare effectively for your CIPS L6M9 Supply Network Design certification with our extensive collection of free, high-quality practice questions. Each question is designed to mirror the actual exam format and objectives, complete with comprehensive answers and detailed explanations. Our materials are regularly updated for 2026, ensuring you have the most current resources to build confidence and succeed on your first attempt.

Joy is a Senior Accountant at Big Fish Ltd. The organisation is a manufacturing company that specialises in sporting and camping goods such as tents, fishing rods, and archery equipment. These items are produced using imported raw materials from a variety of suppliers, many of whom arebased in low-cost countries. Joy is assessing the extent to which the organisation may be vulnerable to cost increases and fluctuating currency values. What is Joy completing?

Which of the following is adifferencebetween a supply chain and a supply network?Select ALL that apply.

Which of the following is considered aprimary activityin theValue Chain?

Which area ofoperations strategyis concerned withinformation management systems, automation, and productivity?

A cupcake manufacturing organisation uses a 'management by exception' technique when it comes to planning and control. What does this mean?

Maxi Ltd is a medium-sized manufacturing organisation in the automotive industry that creates engines for cars. It has traditionally worked well with its suppliers, with strong relationships and regular meetings. There are currently around 15 suppliers who provide parts to Maxi Ltd.

Due to changing customer demands, Maxi Ltd will, from next month, modify the manufacturing of some of its products. Product X is being made more environmentally friendly, with output of CO2 being reduced by 32%. The product will take longer to produce, but there will be no additional cost to customers for this.

Maxi ltd are considering outsourcing the manufacturing of Product Y as it is not a product which is routinely ordered by customers. This will allow Maxi Ltd to focus on other products which generate higher revenues for the company. The concern within the Board of Directorsis that if demand increases for this product, an outsourced company may not be able to cope with higher numbers of orders.

Product Z is an extremely popular item and oftentimes Maxi Ltd does not have the capacity to fulfil all orders. Consideration has been given to increasing the size of the factory, but this has been discarded as risky as demand is not guaranteed. The product has been available on the marketplace for a short amount of time and sales are continuing to increase, but the company believes this will soon plateau. To deal with current demand, the marketing team is working on campaigns to invite customers to make orders for this product at certain times of the year when product X is not being created in the factory. This means resources can be reallocated to the creation of product Z.

What is themain concernregarding the option to outsource the manufacturing of product Y?

Maxi Ltd is a medium-sized manufacturing organisation in the automotive industry that creates engines for cars. It has traditionally worked well with its suppliers, with strong relationships and regular meetings. There are currently around 15 suppliers who provide parts to Maxi Ltd.

Due to changing customer demands, Maxi Ltd will, from next month, modify the manufacturing of some of its products. Product X is being made more environmentally friendly, with output of CO2 being reduced by 32%. The product will take longer to produce, but there will be no additional cost to customers for this.

Maxi ltd are considering outsourcing the manufacturing of Product Y as it is not a product which is routinely ordered by customers. This will allow Maxi Ltd to focus on other products which generate higher revenues for the company. The concern within the Board of Directors is that if demand increases for this product, an outsourced company may not be able to cope with higher numbers of orders.

Product Z is an extremely popular item and oftentimes Maxi Ltd does not have the capacity to fulfil all orders. Consideration has been given to increasing the size of the factory, but this has been discarded as risky as demand is not guaranteed. The product has been available on the marketplace for a short amount of time and sales are continuing to increase, but the company believes this will soon plateau. To deal with current demand, the marketing team is working on campaigns to invite customers to make orders for this product at certain times of the year when product X is not being created in the factory. This means resources can be reallocated to the creation of product Z.

Whatcapacity strategyis being used for product Z?

Strategic stocking decisions are likely to change under what circumstances? Select ALL that apply.

According toFoster's Model of Operational Balance, how shouldbusiness strategybe developed?

The operations department of ABC Ltd has recently launched a new product. The product is manufactured within a large factory and then sent to retailers for sale. The department has a system in place which details the components required for the product and the quantities required to fulfil customer demand. The system works online and links to other areas of the business including HR and finance.

So far, several large orders have been placed for the product from different retailers. The Chief Operations Officer (COO) has decided to programme the completion of the orders based on when the orders were placed. The benefit of this strategy is that it will give each customer a similar lead time. Thus far no buffer stock has been created as products are only created when orders are received.

Three teams are required to make the product and the product flows from team one to team two to team three, each team adding a component to the product. Unfortunately, team two are short staffed and are completing their work at a slower rate than the other two teams. This is a huge consideration for the COO as it will impact upon the capacity of the organisation.

The retailers have all signed contracts with ABC Ltd and the COO is extremely happy that they are long term contracts. Contract 1 is with retailer X and the price is set for three years. Contract 2 is with retailer Y and is a five year contract where the price will be reviewed annually in line with CPI. Contract 3 has a variable pricing mechanism based on the volume of products ordered.

What pricing mechanism is being used with supplier Y?

What does a forcefield diagram show?

Which of the following are examples of investment appraisal techniques? Select ALL that apply.

In a bottom-up process for planning and control, who would make the strategic plan?

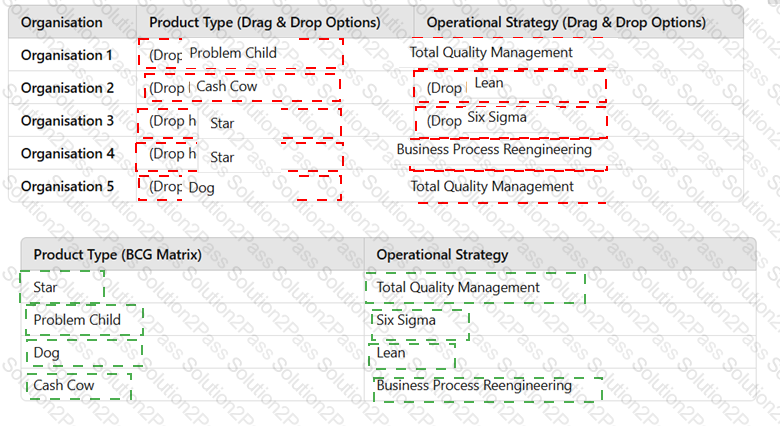

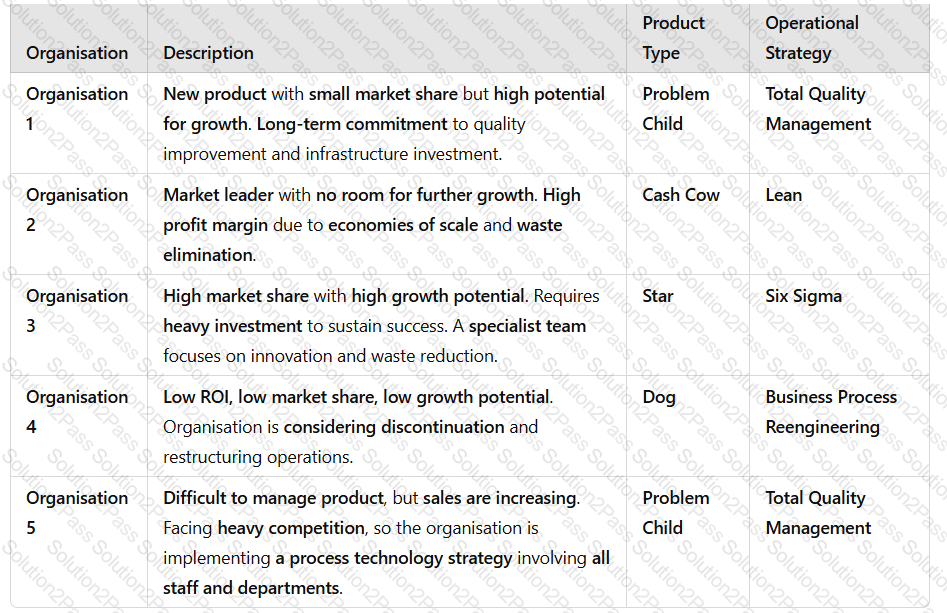

Scenario:

Five manufacturing organisations are working withdifferent productsand usingvarious operational strategies. Each product aligns with acategory from the Boston Consultancy Group (BCG) Matrix, and each organisation is implementing aspecific operational strategy.

For eachorganisation, select thecorrect Product TypeandOperational Strategy.

Which of the following arebenefits of optimising the supply chain?Select ALL that apply.

Company A manufactures wheels for Company B, which manufactures cars. Traditionally, Company A would complete the wheels and conduct quality assessments before sending them to Company B, which would then begin assembling cars. However, a new CEO at Company B has introduced atechnology systemthat enablessimultaneous production, meaning Company B starts manufacturing cars at the same time Company A begins producing wheels.

What is this new system known as?

XYZ Ltd is a manufacturing organisation that buys raw materials from ABC Ltd, including rare materials such as rubies and gold. XYZ Ltd acceptsallorders from ABC Ltd as the materials are rare, making the relationshipone-sided. Which type of network best describes this relationship?

Dev is creating anOperations Strategyfor hishealthcare consultancybusiness. Which of the following describes anOperations Strategy? SelectALLthat apply.

Linear Programming (LP) can be adopted bymany business functions. Who out of the following could use LP modelling?Select ALL that apply.

Rayan is the new CFO of an international banking organisation operating in London. He has been invited to a meeting of the top executives regarding corporate strategies and strategic resource planning. He believes that the organisation must be led by the strategy first, with resources then created to meet the requirement. Is this always the case?

A screenshot of a product description

AI-generated content may be incorrect.

A screenshot of a product description

AI-generated content may be incorrect.